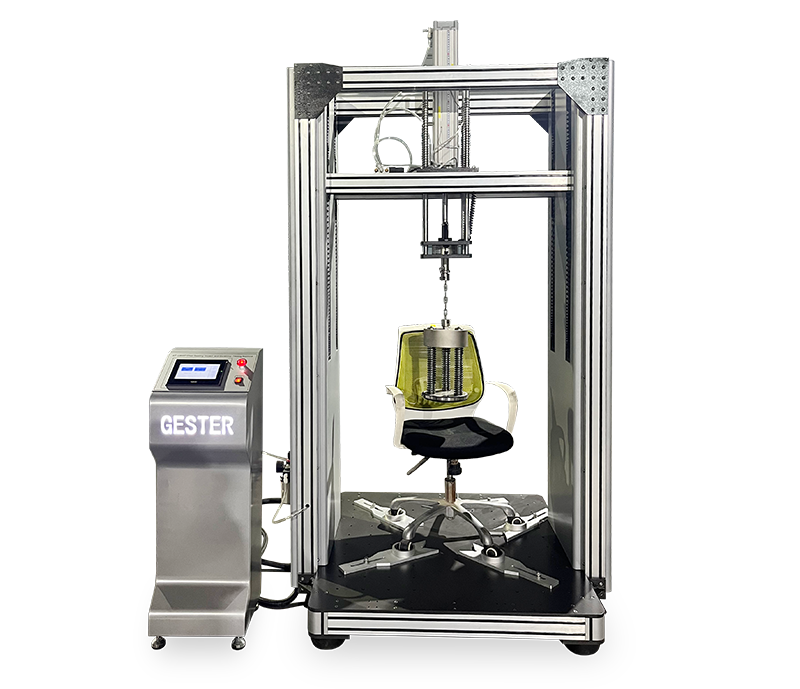

What is the Chair Seating Impact and Durability Testing Machine GT-LB05

Apr 10, 2024

What is the Chair Seating Impact and Durability Testing Machine GT-LB05

Introduction:

In the realm of furniture design and manufacturing, ensuring the quality and durability of chairs is paramount. Chairs are subjected to various stresses and strains daily, particularly through prolonged usage. Thus, the chair testing machine emerges as a crucial tool in evaluating the resilience of chairs against impact forces and fatigue stresses. This article delves into the intricate functionality and significance of chair seating impact and durability testing machine, offering insights into its application and operational procedures.

Understanding the Purpose:

The chair durability testing machine is designed to execute two essential functions: chair seating impact testing and seating durability assessment. These tests are instrumental in gauging the robustness of chairs against both sudden impact forces and the wear and tear induced by regular usage. By subjecting chairs to rigorous testing protocols, manufacturers can ensure compliance with quality standards and enhance consumer confidence in their products.

Operational Procedure:

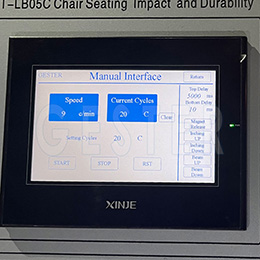

The operational procedure of the chair seating durability testing machine is systematic and user-friendly, ensuring precise testing parameters and accurate evaluations. The following steps outline the operational sequence:

1:Turn on the power.

2:Select English operation interface.

3:Place the sample on the machine, aligning the cylinder with the center position of the chair.

4:Place the chair legs in the designated position and secure them with screws.

5:Click [Beam up] to adjust the appropriate height of the cylinder crossbeam to place the impact head.

6:Click [Beam down] to adjust the impact head to the appropriate position, use tool to connect and fix the impact head.

7:Click [RST] to lift the cylinder and return the impact head to the original position.

8:Click [Beam up] and [Beam down] to adjust the height of the cylinder crossbeam to achieve a height of 152mm from the bottom of the impact head to the surface of the seat.

9:Click to setting cycles.

10:The impact frequency can be adjusted by setting [Top Delay].

11:Click [Clear].

12:Click [Sart] to start test.

13:After reaching the set number of impacts, the machine will automatically shut down.

14:Test completed, please check if the chair is damaged.

Significance:

The significance of the BIFMAX5.1 chair testing machine lies in its ability to provide accurate and reliable assessments of chair quality and durability. By subjecting chairs to simulated impact forces and fatigue stresses, it facilitates the identification of potential weaknesses and design flaws, enabling manufacturers to enhance product quality and longevity. Moreover, adherence to standardized testing procedures ensures consistency and comparability across different chair models, fostering consumer confidence and satisfaction.

In conclusion, the chair testing machine emerge as an indispensable tool in the realm of furniture design and manufacturing. Its comprehensive functionalities and precise operational procedures enable thorough evaluations of chair quality and resilience. By facilitating the identification of design flaws and weaknesses, it paves the way for continuous improvement in chair design and manufacturing processes, ultimately enhancing consumer satisfaction and confidence in the products.