What is the Purpose of the Sponge Resilience Tester ?

Jun 24, 2025

What is the Purpose of the Sponge Resilience Tester ?

The Sponge Resilience Tester is a steel ball falling freely on a soft foam or other elastic material sample. An instrument for determining the rebound height of polyurethane elastomer materials.

Test Principle

The Foam Resilience Tester calculates the rebound resilience of the foam plastic by dropping a steel ball of specified diameter and mass from a defined height onto the foam sample and then calculating the percentage ratio of the maximum rebound height of the steel ball to its drop height, known as the rebound rate. The rebound rate is used to express the resilience of the foam plastic.

The Foam Constant-load Pounding Fatigue Tester is mainly used to measure the rebound properties of polyurethane elastomers, foams, plastics, sponges, and other materials. After the material is molded, it should be stored for at least 72 hours and then conditioned for at least 16 hours at 23±2°C and 45-50% relative humidity before testing.

How to Operate the Sponge Resilience Tester

Acceptance

Accessory display: Steel ball, magnetic rod

Put the Foam Testing Equipment on the platform and adjust the feet according to the level bubble to make the instrument level.

Connect the power and turn on the power switch.

Operation

Prepare a 100 mm x 100 mm x 50 mm specimen (Note: If the thickness is insufficient, the stacking method can be used).

Put the sample into the specimen holder.

Turn on the emergency stop switch.

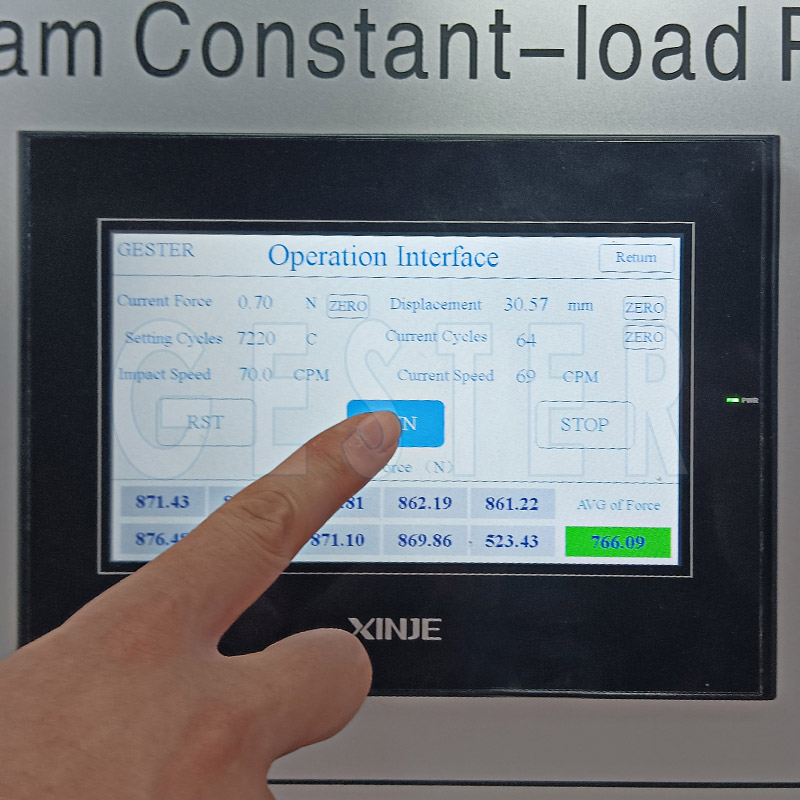

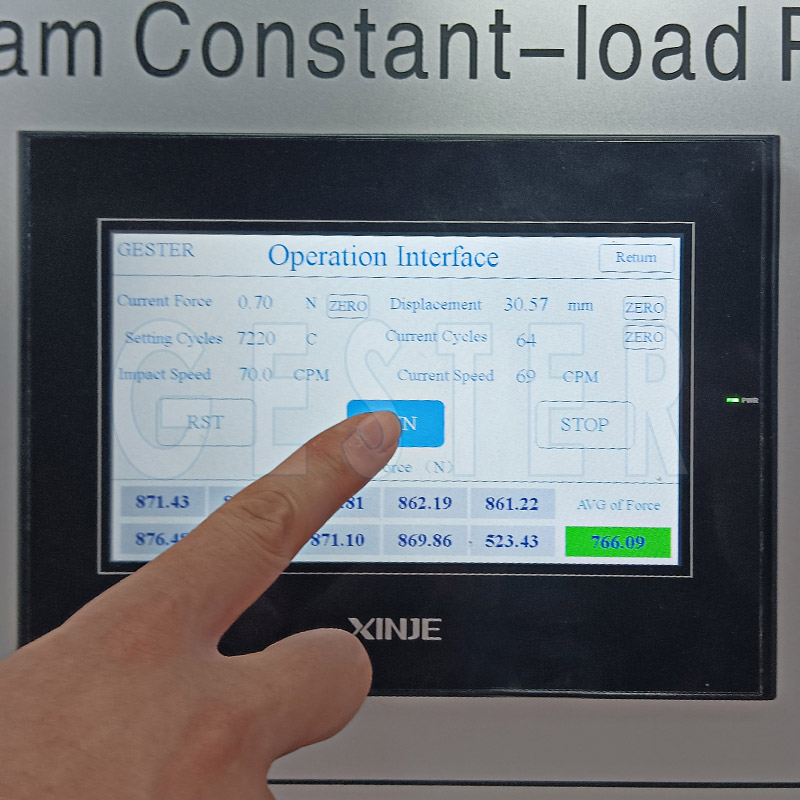

Enter the main interface.

Click “Del All” to clear all data, click “Del Cur.” to clear current data.

“UpperL./LowerL.” deviation setting: Can be set according to your needs.

Click to select “460mm” or “500mm” as desired.

If choose 460mm, please adjust the plexiglass tube to 460mm position.

If choose 500mm, please adjust the plexiglass tube to 500mm position.

Turn the mechanical magnet to ON and install the steel ball.

Click the “Test” button, turn the mechanical magnet to OFF position, the steel ball falls freely, completes a test, and displays the test result value.

Use the magnetic rod to draw steel ball out, and reinstall it to test again.

Each group should be tested three times and completed within 60S. After completing all tests, click “Print” to print the results.

Comparison Between Motorized and Manual Ball Release Mechanisms

Manual release: the principle of manual release of steel ball is to suck the steel ball through the magnet on the handle, and then make the handle and the steel ball separate by human external force, this method may cause deviation and rotation during the ball's descent, potentially resulting in off-center contact between the ball and specimen, or contact with the container wall, and because operators may perform the release differently each time, it will also produce errors on the results, affecting the success rate of the test. These factors collectively impact the test's success rate.

Electric release: The steel ball is vertically aligned below the electromagnet and in the centre of the plexiglass tube, and then the electromagnet loses its magnetism after the power failure and falls down freely, and then bounces back after contacting with the specimen, which greatly improves the efficiency of the test and the reliability of the data. This method complies with standard requirements prohibiting ball rotation and mandating centered positioning during descent.