Telefone :

+ 86 018059983973Fax :

+86-595-22515221Email :

sales3@gester-instruments.comAdicionar :

7/F, No.15, Chifeng Road, Licheng Region, Quanzhou city of Fujian PR,China.What Tests Are Needed for Reliable Transport Packaging?

A Complete Guide

According to statistics, the annual global losses caused by cargo damage due to packaging failure reach a considerable amount. Whether it is small parcels, large industrial equipment, or professional packaging for precision instruments and fragile goods, once scientific reliability testing is not passed, it will not only cause direct economic losses, but also affect brand reputation, increase after-sales costs, and even trigger customer complaints and cooperation disputes.

So, what tests are actually required for a truly reliable transport packaging system? What problems does each test solve? And how should appropriate testing equipment be selected?

During cargo transportation, packaging is subjected to a combination of stresses such as vibration, impact, dropping, and compression. For example, continuous vibration caused by long-distance road or railway transportation, as well as unavoidable drops and collisions during loading and unloading.

If the packaging structure, cushioning design, or material selection is improper, even if the product itself is of excellent quality, it may still be damaged during transportation. Therefore, transport packaging testing is intended to simulate real transportation risks in advance, identify weak points in packaging design, and prevent problems such as damage, deformation, and leakage during actual transportation.

This test simulates various road conditions encountered during transportation, such as bumps, uphill and downhill movement, and turning, thereby simulating collisions and compression occurring inside the vehicle, which may lead to product damage.

Aimed at heavy equipment, industrial products, or full-pallet transport packaging, suitable for high-load and high-intensity vibration simulation.

Simulates the free-fall impact suffered by products during transportation and handling.

Designed for large industrial packaging and heavy equipment transportation, addressing the insufficient load capacity of traditional drop testing equipment.

Tests the compressive strength of standard-size corrugated cartons or packaging boxes and containers made of other materials.

Test the ability of product against impact damage in the real environment, such as handling, stacking of shelves, sliding motor, loading and unloading of locomotives, transportation of products, etc.

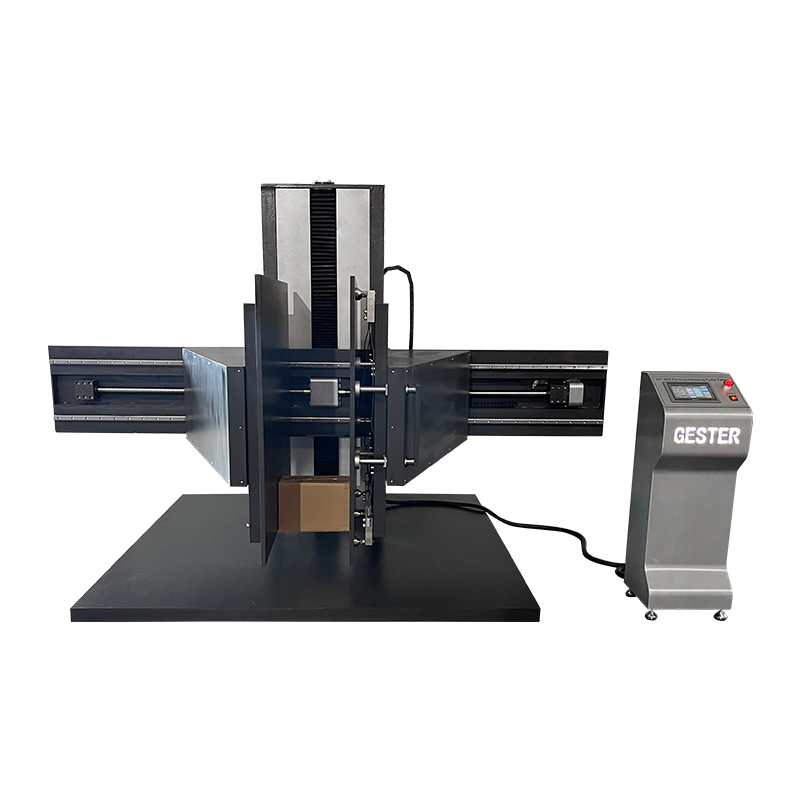

Simulates scenarios where clamp vehicles load and unload packages, testing the impact of clamping force between two plywood boards on packages and goods.

In practical applications, enterprises need to select appropriate test items, testing equipment, and testing standards based on their own product characteristics (weight, size, material, fragility), packaging type, and transportation scenarios (transportation mode, destination environment). Before products leave the factory, comprehensive testing helps avoid logistics risks. Alternatively, according to your industry, you may consult our professionals to provide equipment suitable for your products.